A Cost Effective and Safe Alternative to Micro Bulk

For more than 60 years, Noble Gas Solutions has delivered gases, as well as hard goods, to customers throughout upstate New York’s Tech Valley region and into southern Vermont and western Massachusetts. It does so from its location in Albany, NY and from a branch location in Kingston, NY.

David Mahoney, President of Noble Gas Solutions, notes that his business model started beating to a different rhythm in 1996, shortly after he acquired his Kingston branch location. That new rhythm has led to a notable percent increase in his specialty gas business in the last

15 years, fueled in part by a 200% uptick since 2008, in gases provided for research and development applications. Mahoney stated that while his business mix of 40-percent hard goods, 60-percent gases (up from 45 percent gases prior to 1996) is healthy, he would have no problem if his gas business grew to be 65 or 70 percent of the company.

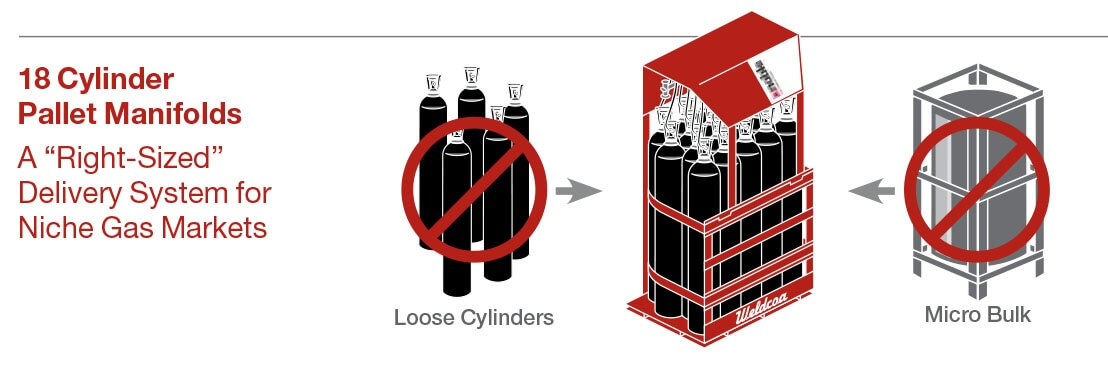

A Terrific Alternative

“When we acquired the branch location,” Mahoney explained, “I looked closely at how we were bringing cylinders into the branch. Looking through the Weldcoa literature, we saw that they manufactured 18-cylinder pallet manifolds. We recognized these manifolds as a terrific alternative to costly microbulk delivery vehicles for safely delivering higher volumes of gas.”

Noble Gas now has more than 200 Weldcoa pallet manifolds in service for specialty gas and industrial gas applications. It has palletized the majority of its fleet with the 18-cylinder pallet manifolds.

Gases packaged in the pallets include:

Argon • Oxygen • Carbon Dioxide • Ethane • Helium • Nitrogen • Carbon Monoxide • Hydrogen

Industrial process applications include:

Blanketing and Inerting • Pipeline Purging • Cold-Storage Applications • Cold-Shrink Processes • Combustion Applications

Custom Packaging for Clients

“We also have packaged argon mixtures for welding applications in the pallet manifolds,” added Mahoney. “And the Weldcoa package has really helped us kick up sales to research and development laboratories. We’ve had situations where a customer has asked us to package different types of gases—oddball flammable mixes, for example, for proprietary research—on the pallet manifolds, and we’ve been able to deliver.”

“We recongnized that Weldcoa's 18-cylinder pallet manifolds were a terriffic alternative to costly micro bulk delivery vehicles for safely delivering higher volumes of gas.”

David Mahoney, President of Noble Gas Solutions, Inc.

Delivering An Entire Pallet Not Loose Cylinders

What does the pallet manifold mean to Mahoney and Noble Gas’s customers? “In one word, efficiency,” said Mahoney. “By moving from individual cylinders to the clusters, we’ve saved our customers countless hours in labor for cylinder handling. The installations we’ve done allow the customer to no longer have to touch the cylinder. We deliver a new pallet, pick up the old one, and all the customer knows is that their gas supply is constant. As a result, they’re more efficient, and we’re more efficient. We don’t have to move 18 separate cylinders—just the pallet. We’re also more efficient in our plant. Filling is more efficient, cleaner and safer. And it’s a nice-looking package.”

“Whenever we see an application for the 18-cylinder pallet manifolds, whether at an existing customer or a competitive opportunity, we sell the package. Actually, the package sells itself. The pallet manifolds have helped us differentiate ourselves in the market, and enhance our relationships with customers. But what really sells the package is the fact that none of our 18 packs will vent to the atmosphere. Once the client understands that, the sale is ours.”

David Mahoney, President of Noble Gas Solutions, Inc.