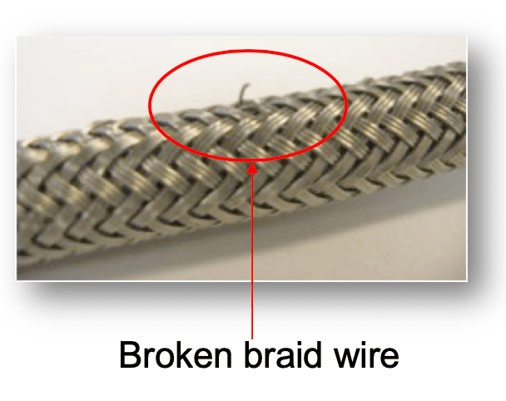

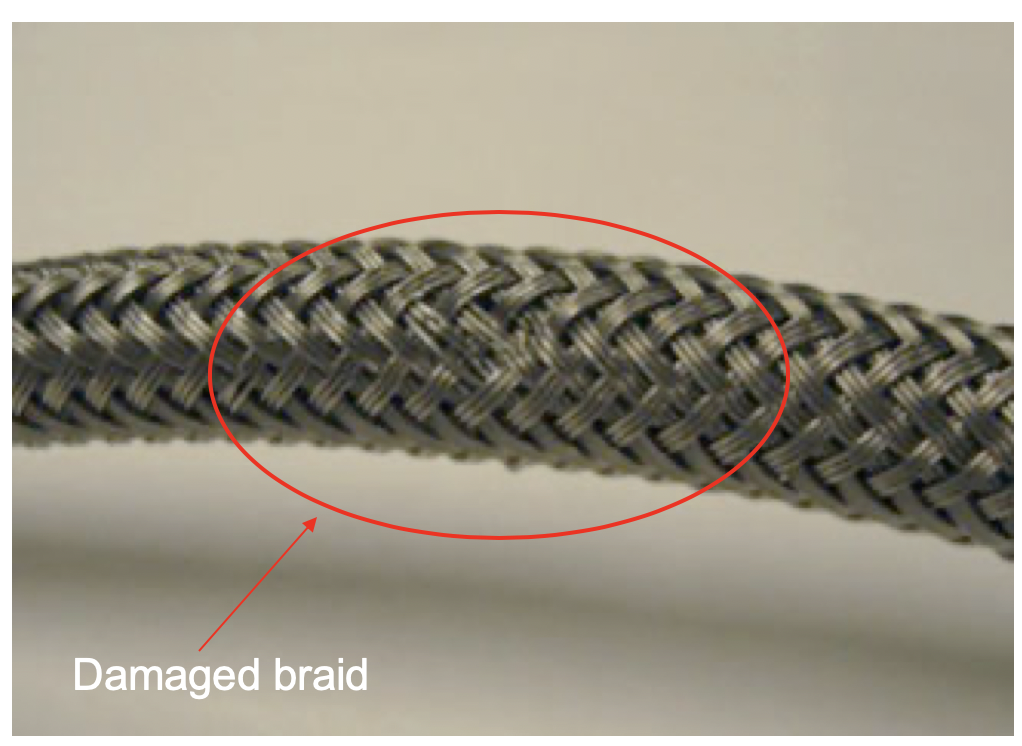

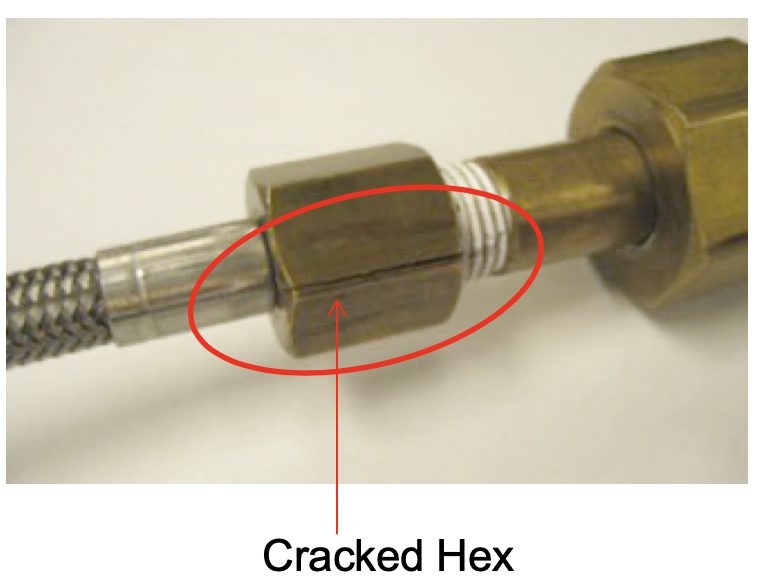

A visual inspection is the most important check that can be done to prevent a lead failure. Visual inspections should be conducted on a regular basis depending on the application and service. Regular basis is considered monthly, weekly or daily.

Minimum marking requirements are as follows:

In the event an assembly is in application and is not clearly marked the following is recommended:

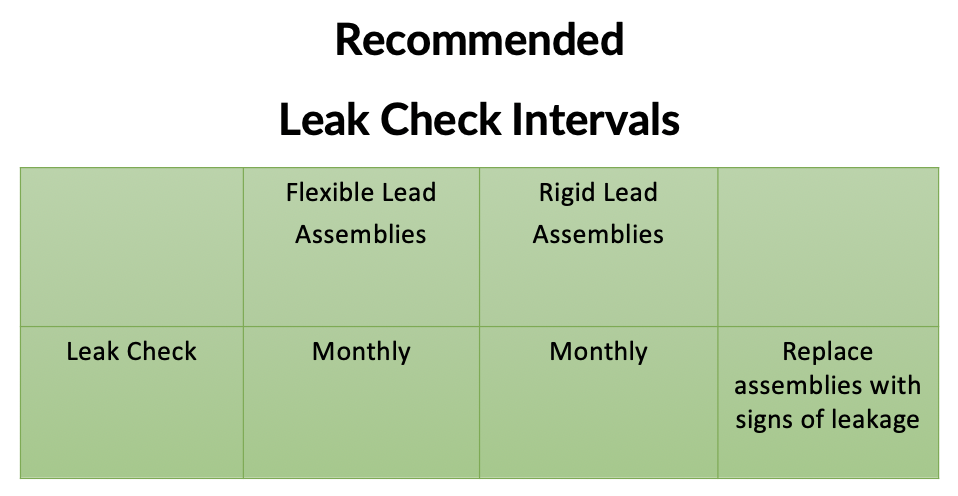

All flexible lead assemblies must be leak checked periodically to ensure assembly integrity and safety.

Typically a lead is the last item to be specified in a system. In doing so the lead usually is not placed on a maintenance program and subjected to over use.

Please Note: Fill System Leads (Double Braided/Post Sintered/3600 PSI MAWP) should be visually inspected every morning prior to the first fill of the day to detect any kinks, frays in the stainless-steel weave or discoloration of the leads. If any leads are found to have kinks, frays or discoloration the lead needs to be replaced immediately. (You should never use a damaged lead during the fill process.) In addition, the leads should be leak checked during every fill cycle.

Please Note: Gas Pack Leads (Double Braided/Post Sintered/3600 PSI MAWP) should be visually inspected before each fill to detect any kinks, frays in the weave or discoloration of the leads. (Gas Packs used in acidic or reactive atmospheres may suffer discoloration.) If any leads are found to have kinks, frays or discoloration the lead needs to be replaced immediately. (Isolate the pack until the damaged lead has been replaced.) In addition, the leads should be leak checked during every fill cycle.

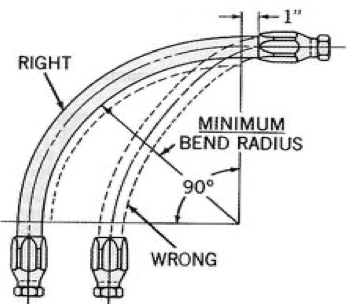

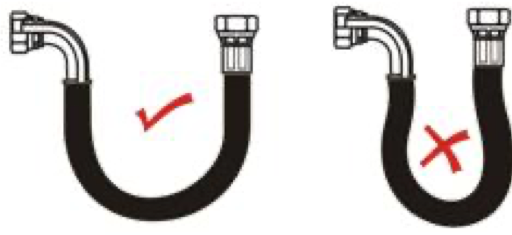

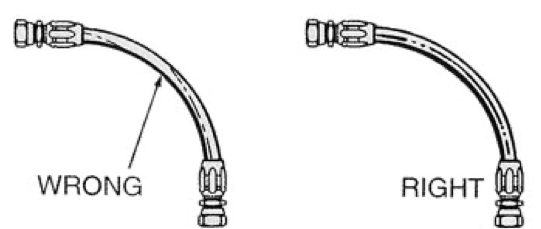

This section is intended to provide some general information regarding lead installation.

For any questions, please feel free to contact us at (630) 806-2000 or email us at sales@weldcoa.com

Ensure that the products and services you depend on are of the highest quality, and will be there when you need them, time and time again.

We’ve adapted to a new way of working, in order to meet new expectations. We’re better, stronger, and will respond with greater agility. More than ever before, we are committed to delivering quality, Made in the USA products and services, that you can always depend on, and that will contribute to the success of your business.

We want to partner with you, providing real long-term value.

Located in Aurora, IL, Weldcoa is an innovative US manufacturer of products that store, transport, fill, supply and/or analyze compressed gas, cryogenic liquids, high pressure liquids and supercritical fluid. Our cross-disciplinary team of experts bring an in-depth knowledge of gases to every project. You can count on their passion and commitment to make your project a success.

Call 630-806-2000 or email us at solutions@weldcoa.com today to get started.