![]()

Weldcoa’s automation was designed by seasoned people who filled cylinders for a living. Systems can be installed into new or existing facilities. The touchscreen PLC automates all of the responsibilities of the traditional human cylinder filler creating a safer environment, uniform product fill, maximum production and new levels of management control/simplification of training. Our automated cylinder fill systems have been validated by some of the largest gas manufacturers in the world.

LEADING, PROVEN TECHNOLOGY:

Weldcoa constantly reviews new products on the markets that could enhance our systems. For that reason our systems are always current state-of-the-art. Our automation staff is all in-house and with 20+ years of systems in operation, the staff is very knowledgeable on overall cylinder filling plant operations. So with this understanding the logic that is built into each system is very thorough.

It is like someone, who fully understands the ins and outs of cylinder filling, is standing there and operating the system. Which is exactly what is happening. Weldcoa has a number of engineers on staff who have worked in fill plants for the major gas companies. They have worked with our automation programmers to ensure that this logic is built into the system.

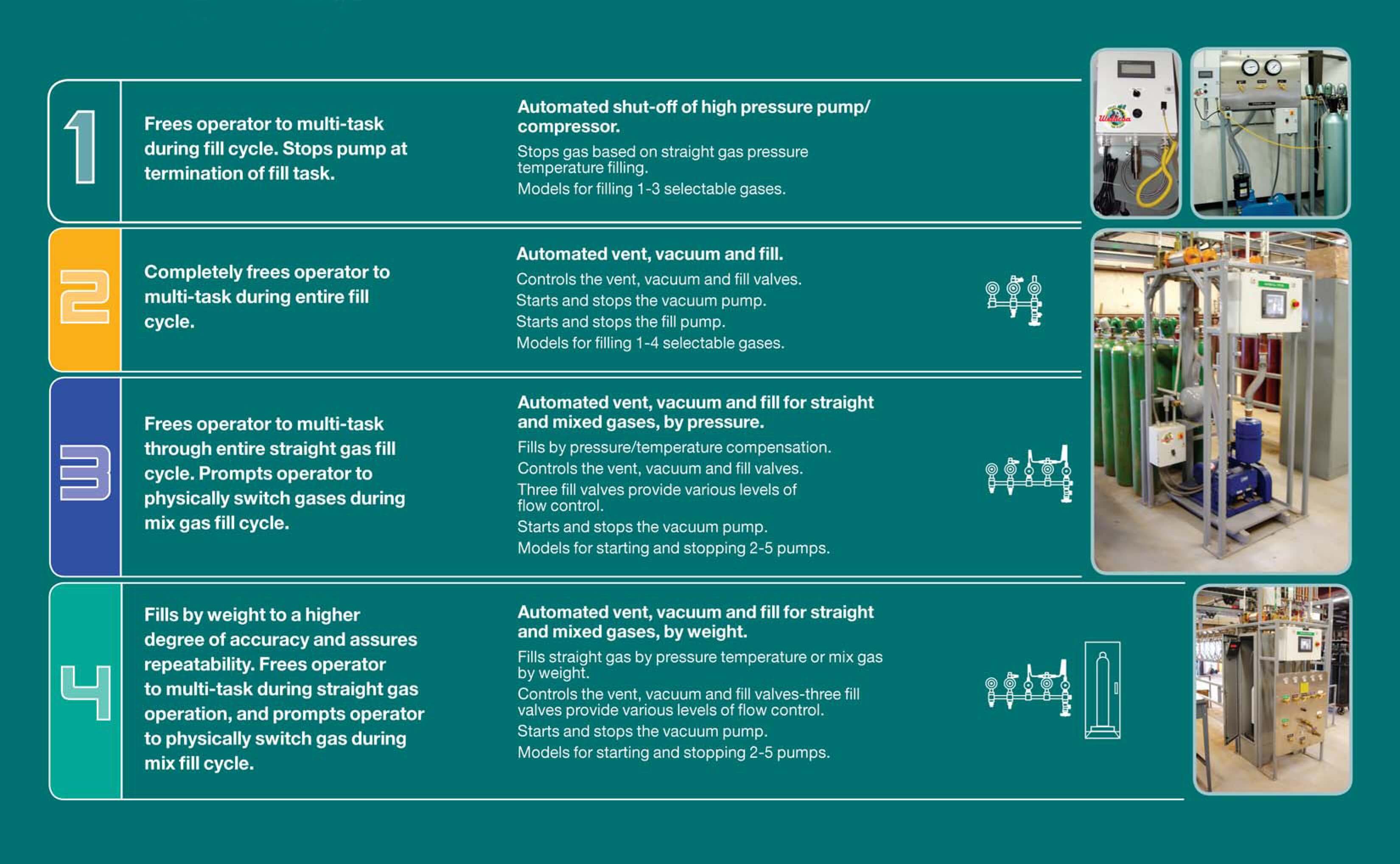

It is easy for anyone to say they offer automation. However, you really need to look at what you are actually getting and understand what the automation will do for you. This can have a tremendous impact on the efficiency of the system.

SECURITY:

Because many companies have a concern with an outside company having access to the computer system for the automation, Weldcoa has recently come up with a solution. This system provides Weldcoa remote access without going through any of the company’s channels or systems. Thus security is guaranteed and companies can be assured of no breaches into their systems.

There are many reasons why to choose a Weldcoa automated fill plant. The primary reason though is that they work and perform. We have a long, proven track record of successful systems and satisfied clients. Don’t be misled by a cheaper price on the bottom line of a quote for the equipment. Make it a point to fully understand the overall costs.

ELECTRICAL:

All electrical control panels for our systems are made in-house with a UL listed shop. All automation is fully tested and proven prior to shipment. Electrical schematic wiring drawings are provided for the local electrical contractor and a meeting is held with the contractor prior to the installation. All final wire connections are inspected by our electrical engineer to ensure proper installation. These steps greatly minimize any start-up and operational issues with the system which is another cost savings.

MECHANICAL:

Drawings for the piping (P&ID’s) for each gas system are provided to the customer. Cut sheets for all equipment components are also provided for repair and spare parts information. All of this is stored on the HMI operator screen for ease of use and to find readily.

Our palletized automated fill islands are pre-assembled in our shop including mechanically and electrically. They are operationally tested prior to shipment and then prepared for shipping. Once on the customer site the island can be set up in 1 – 1-1/2 days. All piping is cleaned and capped at one end of the island for ease of piping in the field. The ease of installation dramatically cuts down the costs of the installation.

PUMPS AND CONTROLS:

The heart of any pumping system is the pump itself. If the pump fails for any reason then your production is down and that is costly. For that reason Weldcoa’s automation provides a number of checks for the proper operation and will send you alarm email alerts of any pump issues. It also tracks the performance and utilization. With the remote support set-up, we are proactive in keeping your pumps operating and eliminating as much unplanned down time as possible.

Weldcoa is the only company that predominantly uses variable frequency drives (VFD’s) on the pumps. This allows our automation to control the pump speed at any time. This is one of the keys to the success of the system with its accuracy for mixtures. Besides mixtures this allows us to slow the pump down when filling smaller type cylinders including CO2, control the speed for heat of compression, use a higher capacity pump when needed for filling tube trailers or large volumes, to ramp up the speed of the pump instead of instantaneous start-up.

We also include electrical boxes out at the pump pad that houses the thermocouples used for monitoring the pumps. This allows for simple electrical installation for these devices which can add up to real savings.

START-UP AND TRAINING:

Because of the preliminary work done for the electrical and mechanical along with it already tested in the shop, the start-up is easy to debug and usually only takes 2 – 3 days to get everything functional. Our automation programmer is on site during this time to make sure all the programming meets your satisfaction and your specific SOP’s. We will train your operators on all phases of the systems. The HMI is user friendly with very simple easy to read screens with touch screen operation. Thus your system is up and running fully in no time at all.

Our fill plant solutions are designed and built to exceed your expectations. We work closely with you and will manage your project from start to finish. Weldcoa has decades of experience in successfully helping businesses, just like yours, transition from what was to what will be.

Holston Gases Tells Their Fill Plant Story

Encore Welding Talks About Their Weldcoa Experience

WestAir Tells Us How Their UpGrade Transition Has Been

![]()

![]()

Weldcoa is a true U.S. manufacturer with the people, equipment and experience necessary to design, manufacture and test a wide range of products and automation for compressed gas, cryogenic liquids and supercritcal CO2. Our elite team of engineers, programmers and support staff are heavily involved in every detail of our products from research and development to installation and start-up and training. Often, the team that designs your solutions is the very same team who installs and provides the long-term support for the equipment. Everyone at Weldcoa is focused on providing you with the highest possible level of service and support.

If you are interested in discussing your project and/or application with us, please contact us at (630) 806-2000 or email our team at solutions@weldcoa.com today. We would be happy to hear from you!

We want to partner with you, providing real long-term value.

Located in Aurora, IL, Weldcoa is an innovative US manufacturer of products that store, transport, fill, supply and/or analyze compressed gas, cryogenic liquids, high pressure liquids and supercritical fluid. Our cross-disciplinary team of experts bring an in-depth knowledge of gases to every project. You can count on their passion and commitment to make your project a success.

Call 630-806-2000 or email us at solutions@weldcoa.com today to get started.